Clay is a finely-grained natural rock or soil material that, along with other materials such as stone and wood, has been used for construction for thousands of years. It is composed of one or more clay minerals (such as kaolinites or smectites), sometimes with small quantities of quartz, metal oxides and organic matter. Clay is formed very slowly as a result of weathering and erosion of rocks containing the mineral group known as feldspar.

Typical structural clay products are building brick, paving brick, terra-cotta facing tile, roofing tile, and drainage pipe. These objects are made from commonly occurring natural materials, which are mixed with water, formed into the desired shape, and fired in a kiln in order to give the clay mixture a permanent bond. Finished structural clay products display such essential properties as load-bearing strength, resistance to wear, resistance to chemical attack, attractive appearance, and an ability to take a decorative finish.

At least half of the world’s population live or work in a building made with clay as an essential part of its load-bearing structure. Many natural building techniques use clay as a primary material. Adobe, cob, cordwood, and rammed earth structures all use clay as well as building elements such as wattle and daub, clay plaster, clay render, clay floors and clay paints and ceramic building materials. Mortar in brick chimneys and stone walls has clay as an ingredient.

Clay mineral classified by its structure and layer type

The interaction between clay minerals depends on their structure. This structure controls the behaviour of clay minerals’ double layer which is the primary generator of repulsive pressure in the double layer model. The forces controlling the repulsive pressure are governed by physicochemical swelling in clay minerals since the attractive forces by comparison are small within the range of the external forces involved in the clay structure. Cations are attracted to external surfaces of clay minerals which are negatively charged and can also be drawn to internal surfaces of expandable minerals, so that clay mineral properties and structure can be changed.

Given below are some clay types that are being used in products in construction across the globe.

Earth plaster

Earth plasters have been used for thousands of years to cover both the interior and exterior of structures made using a variety of construction techniques. From the wide array of our own mined materials and those we import, we have selected a few light colored (and therefore easily pigmented) materials that span a wide range of fluid and dry properties. We describe these materials well in our documentation. You can blend these clays and condition with hardeners, plaster and mineral fillers to make them smooth, easy-to-apply and resistant to wear and weathering. For those with more specific needs, we stock a wide range of useful materials (e.g. naturally pigmented clays or even our standard ceramic mixes).

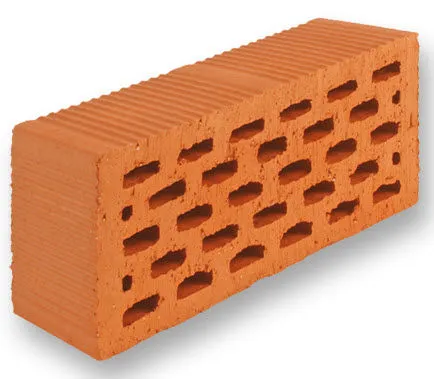

The Brick Clays

These are low grade clays used most for the manufacturing of building bricks and similar clay products. Brick clay is rich in silica, alumina, oxides of iron, calcium, magnesium and organic matter. It is mutual proportion of these components that define their suitability or otherwise for making good quality bricks for building construction. • The oxides of iron, calcium and magnesium act as fluxes that fuse easily at brick-making temperature and bind the alumina and silica particles thoroughly giving the brick desired properties of cohesion and strength.

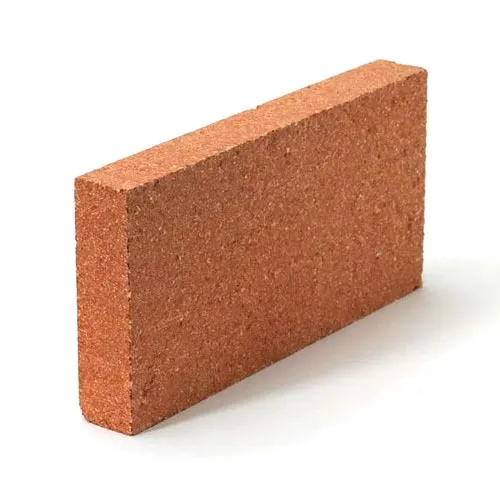

Fired clay

Fired clay is a versatile and robust building material that has a timeless appeal. Clay building products can be used across the whole envelope in the form of bricks, blocks, façade systems, roof tiles and pavers.

As one of the oldest and most popular building materials available, clay bricks and roof tiles are deeply rooted in European history and form some of our most iconic buildings. The trans-generational lifecycle of clay-built structures means that they have become part of our cultural heritage and architectural identity. Today’s products are manufactured much more efficiently than in the past, which results in higher quality and lower environmental impact. However, Wienerberger retains traditional shaping methods for Keymer hand-made roof tiles, to meet the demands of restoration projects and to achieve a heritage look. Clay building products can be used for almost any new build construction or renovation project and can reflect all architectural styles, from traditional and historic to innovative and avant-garde. Architects love to experiment with clay building products as their compact size and the variety of colours and shapes available provide infinite design options when creating contemporary structures.

Porcelain clay

A high-firing fine-grained white clay body that fires to a durable, strong, vitreous ceramic. It is usually pure white because of its high kaolin content and lack of other ingredients like iron that can change the color and properties. Since kaolin is the purest form of clay, porcelain lacks some of the additives that make clay more plastic (stretchy) making it not the most plastic of clay. This gives it the reputation of being difficult to work with—though modern formulations have addressed this.

Stoneware clay

A mid- or high-firing coarse-grained clay body that can be anywhere between buff color to gray to dark brown, because of varying levels of iron and other “impurities”. It is incredibly durable after firing, with little to no absorption (vitreous).

Earthenware clay

A low-firing fine-grained clay body that is typically found in creek beds and other deposits that have been transported by wind and/or water from their location of origin. This transportation aids in the weathering and breaking down of the source rock into clay, and also adds “impurities” like iron, which is what makes earthenware brown, orange, or red, both in the raw state, and after firing.

Because it is fired low, it is more porous and relatively less durable than stoneware or porcelain, but that can be an advantage in some cases. Terra cotta garden planters are a type of earthenware clay, for example, and the fact that they are porous and can “breathe” is a design advantage.

Mudwall clay

Formed of earth mixed with straw. This type of construction was built in “lifts”, or courses, of between 15 and 55 cm depending on the material properties.

Claywall

This involves the insertion of stones into a mudwall mixture formed between shuttering. The best stones were used on the outside face to present an impression of clay mortared masonry

Burnt Clay

Burnt clay are the classic form of clay, created by pressing wet clay into molds, then drying and firing them in kilns. This is a very old building material-the type of clay found in many of the ancient structures of the world. In appearance, these are solid blocks of hardened clay, usually reddish in color. These high-grade burnt clay bricks have no noticeable flaws, but they’re also going to cost more.

Sand lime clay

Sand lime are used as brick by mixing sand, fly ash and lime. Pigments may also be added for color. The mixture is then molded under pressure to form bricks; the materials bond together by a chemical reaction that occurs as the wet bricks dry under heat and pressure. These bricks are not, however, fired in kilns in the same manner as burnt clay bricks

Fly Ash Clay

Fly ash clay are used as bricks and are manufactured with clay and fly ash-a byproduct of coal burning-fired at about 1,000 degrees C. Because fly ash contains a high volume of calcium oxide, this type of brick is sometimes described as self-cementing, since it expands when exposed to moisture. This tendency to expand, however, can also produce pop-out failure. Fly ash clay brick has the advantage of being lighter in weight than clay or concrete brick.

Turf clay

Occasionally referred to as sod, turf construction entails using earth blocks to form walls either on its own or alternating with stone. Turf is commonly laid in a herringbone pattern for added strength.

Shuttered clay

A form of construction which utilises similar raw materials to mudwall, clay or earth mixed with straw, but in this case it is formed inside a shuttering of wood. In some cases brick was used to make a permanent face to hold in the clay or earth infill.

Light Straw-Clay

Straw is coated with a clay binding slip (slurry) and rammed into forms to produce blocks or walls of very low density (and good insulating properties). It has thus been dubbed Light Straw-Clay. Often little consideration is given to the type of clay used. However, this deserves attention. Bond points will have less strength if there are coarse particles between them (e.g. sand), finer particles clays will work the best to bond the straw.

Bentonite for Stucco clay

Highly plastic clays (especially bentonite) are added to stucco mixes to make them stickier, apply better and dry slower. We import and mine bentonites, smectite and hectorite. These clay vary widely in their plasticity, you might find that our best bentonite will work in a much lower percentage than the one you have been using.

Refractory clays

Refractory clays are used to make kiln furniture including saggers. Laguna Clay Company offers both plugged and dry forms of refractory clay bodies. Refractory clay can be fired repeatedly and have a maturing temperature of cone 14 or 2500 degrees Fahrenheit.

Slip clay

Slips are clays formulated to be used in a liquid state. Slips are often used to fill a plaster cast. Properly formulated slip will build up clay particles against the walls of a plaster cast as the water in the slip is pulled into the surrounding plaster cast. Preparing slip requires preparations specific to the ph of the water used. Novice slip casters are encouraged to use pre mixed slip which is available from Laguna Clay Company in a range of firing temperatures and colors. All of our slip selections are available in dry form in amounts 50 pounds and above, so once you accumulate experience you can switch to dry and mix your own slip.

Residual clay

Residual Clay includes all varieties of clays that are found covering the rocks from which they are formed by natural processes. Such clays are pure in their chemical composition that is related broadly to the parent rock. China Clay is the best example of residual Clay.

The Transported Clays

These are the most common clays spread on the earth. They are formed by the disintegration and decomposition of the pre-existing rocks by natural agencies followed by removal and transportation of broken pieces to far off places where they are finally deposited. Hence any such deposit of transported clay will have all the particles transported from many places and different source materials. The transported clay are, therefore quite heterogeneous in mineralogical and chemical composition.

China Clay

It is the purest type of clay containing very high percentage of mineral Kaolinite or Kaolin Al2Si2O5(OH)4. It is Considered high Grade clay and is used for the manufacturing of crockery and other porcelain ware.

Fire Clay

They are also called refractory clay and contain, besides Kaolinite, Silica and alumina in very high temperature without suffering any deformation off shape given to them at the time of moulding. They are mainly used in manufacturing of refractory bricks that are of great importance in many metallurgical, mechanical and chemical operations.

Vitrified Clays

These clays are rich in fluxing compounds like iron oxide and carbonates of calcium and magnesium. These are easily fusible. i.e. cannot withstand high temperatures above 1100 0 C the fluxes get softened and form glass like material that acts as a strong bonding agent between the other clay particles. This results in the formation of a smooth surfaced hard burnt clay products. The Vitrifying clays called hard burnt clay are specially used for manufacturing of facing brick, flooring tiles, sewer pipe and other similar ornamental and dense clay products.

Conclusion

Clay is one of the oldest building materials used in construction to this day. The ability of this natural material to solidify under certain conditions makes it possible to use it for various purposes in the construction of different buildings.

Clay as the defining ingredient of loam is one of the oldest building materials on Earth, among other ancient, naturally-occurring geologic materials such as stone and organic materials like wood. Between one-half and two-thirds of the world’s population, in both traditional societies as well as developed countries, still live or work in buildings made with clay, often baked into brick, as an essential part of its load-bearing structure. Also a primary ingredient in many natural building techniques, clay is used to create adobe, cob, cordwood, and rammed earth structures and building elements such as wattle and daub, clay plaster, clay render case, clay floors and clay paints and ceramic building material. Clay was used as a mortar in brick chimneys and stone walls where protected from water.

Image Source

www.dancingrabbit.org, happho.com, moneycontrol.com, www.ehowcdn.com, unsplash.com, www.theyearofmud.com, designcoalition.org, www.rahisiconstructionsupplies.co.ke, www.refractory-brick.com