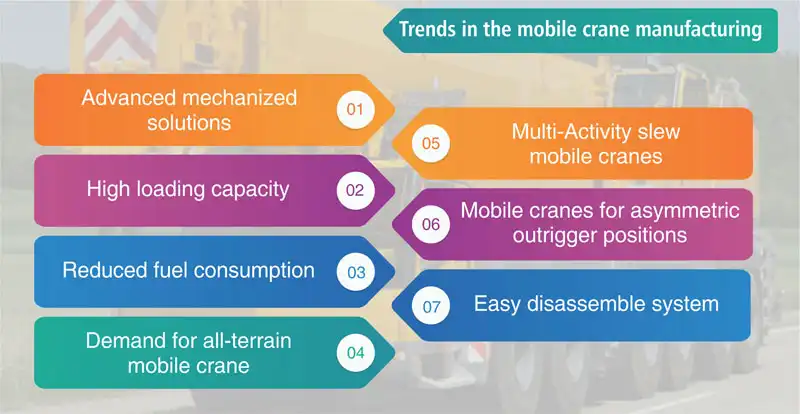

The mobile cranes are being used to address high end works for urban and infrastructure development. Manufacturers are now focusing on creating mobile crane models that would address market demand. From loading capacity to multi-activity everything is being modified to meet the need for the complexity of project sites. This development has been possible with the acceptance of technology and new materials.

Given below are trends that are being focused while manufacturing mobile cranes.

Advanced mechanized solutions of mobile cranes

Manufacturers are now providing advanced mechanized solutions for mobile cranes. From workstation lifting systems to industrial needs, mole cranes are offering Smart Features for projects. The lifting capacity of the supplied cranes varied from 250 kilos to 10,000 kilos. Hybrid overhead traveling cranes can be loaded with smart features that give you control of the material handling in your production processes. New models are simplified fly assembly with new ground-level carrier controls. One control raises and lowers the boom angle from 0 to -3 degrees, and another control is used for the fly assist cylinder.

High loading capacity of mobile cranes

Manufacturers are now providing mobile cranes extending from 35-tonne models to a heavy-duty crane with a load capacity of 1,200 tonnes. High-speed all-terrain mobile cranes. Long booms, enormous load capacities, short erection times and high comfort and safety standards make mobile cranes flexible and economical. These are ideal for public roads and off-road projects use due to their all-terrain chassis. In modern models, stiff boom cranes are available from 14 tons to 40 tons with payload capacities up to 37,000 lbs.

Reduced fuel consumption of mobile cranes

Models are now coming with drive and control systems that offer several optional features that help to reduce fuel consumption and maximize reliability and productivity. With the ECOmode system, the entire pump drive is disengaged automatically when the engine is in idle mode and switched on again in a matter of seconds using intelligent control when power is required. With this system, the software sends signals to the electronic engine, which then automatically adjusts its RPM as per the lifting requirements at the site.

Demand for all-terrain mobile crane

All-terrain crane can perform jobs at heights up to 78m or at a 74m radius without rigging a jib and is ideal for tower crane erection. They are preferred for superior reach and fly-over capabilities, by bringing the maximum system length up to 118m. With the Plus control system, it can calculate the safe lifting capacities of the crane in real-time and for all variations in the crane’s outrigger positions and a counterweight. The system allows a crane to lift beyond the standard 360° load charts, and therefore perform jobs usually reserved for larger machines. Even though all-terrain cranes are compact, they still offer exceptional visibility from the cab to help operators have a full view of the work area. All-terrain cranes are some of the largest, most mobile cranes available today. They combine the best of both worlds: the mobility of truck-mounted cranes and the maneuverability of rough terrain cranes.

Multi-Activity slew mobile cranes

Cranes are now much more than operations; they offer multitasking facilities. They will find application in all areas of infrastructure development, construction of buildings and in industrial use. There is an increased demand for slew cranes. The latest slewing crane lifts its load, suspends that load in mid-air, and then rotates it via a boom rotating mechanism. A mobile crane suddenly gains z-axis capability and greater site versatility. The mobile chassis still conveys the lifter to its destination, but then it can be anchored in place with outriggers while the arcing boom goes about its business in a crowded construction area. This system asset covers every point on a full 360° circle, with the axis of the mobile crane acting as the center of the circle.

Mobile cranes for asymmetric outrigger positions

New hybrid models track the positioning system. This allows both symmetrical and asymmetrical track positions during reduced track width operation, providing optimum lifting performance at any track width. Track width is continuously monitored by the machine and the data is provided. The system is the ideal solution for cranes working in congested job sites at less than full track width. The new model c also includes a single-engine, great highway speed and asymmetric outriggers.

Easy disassemble system of mobile cranes

Manufacturers now provide removable outrigger boxes that disconnect for outrigger beams, boom removal kits and boom float kits which allows driving the boom over the rear on a dolly sometimes. Manufacturers also are focusing on methods of weight saving. To increase payload and meet axle load regulations, end users can easily disassemble certain parts of the crane.

Conclusion

These trends are here to stay and they will dominate the mobile crane manufacturing market. Manufacturers are now spending on research and development for further modification in their machinery system.

Image Source: Kells Crane, TIl, Manitou, Liebherr