A reinforced earth wall is designed and constructed to resist the lateral pressure of the soil and supports the soil laterally so that it can be maintained at different levels on both sides. The lateral pressure could be also due to earth filling, liquid pressure, sand, and granular materials. The walls are used to bound soils between two different elevations often in areas of terrain possessing undesirable slopes. These walls are an economical way to meet every-day earth retention needs for highway and bridge grade separations, railroads and mass transit systems. They are also used in response to difficult design conditions such as very high structures, restricted space, where obstructions within the soil mass are present.

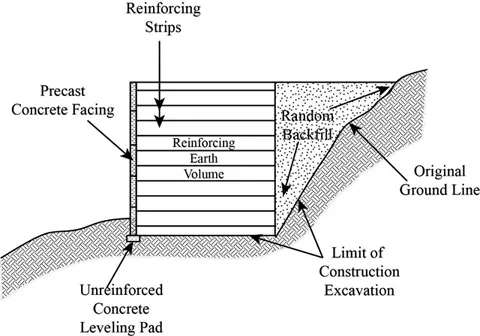

Components of Reinforced Earth Wall

A reinforced earth wall comprises various components that are necessary for the stability and functions of the structure. Each of them are analysed below.

Reinforcement elements

A variety of materials can be used as reinforcing material. These include steel, concrete, glass fiber, wood, rubber, aluminum. There are two types of reinforcements, namely Galvanized Steel reinforcement and Geosynthetic reinforcement.

Galvanized Steel reinforcement is used for high static and dynamic design load, high walls, bridge abutments, heavy duty mining, and industrial retaining wall railway. The strips may be galvanized or black and are designed to be bolted to the tie strips at the back of each facing panel. The Geosynthetic reinforcement is made of high density polyethylene, polyester, and polypropylene which become efficient solutions when the chemical characteristics of the backfill are not suitable for the utilization of galvanized steel.

Backfill elements

A granular backfill has to be used as a reinforced volume structure. As one of the most principal components of reinforced earth wall, the backfill has to meet with mechanical and electrochemical properties of soil. The fill material for reinforced earth structures must be cohesionless and it should have an angle of on interface friction between the compacted fill and the reinforcing element . Crushed concrete, Fly Ash and other recycled material can be used successfully as backfill.

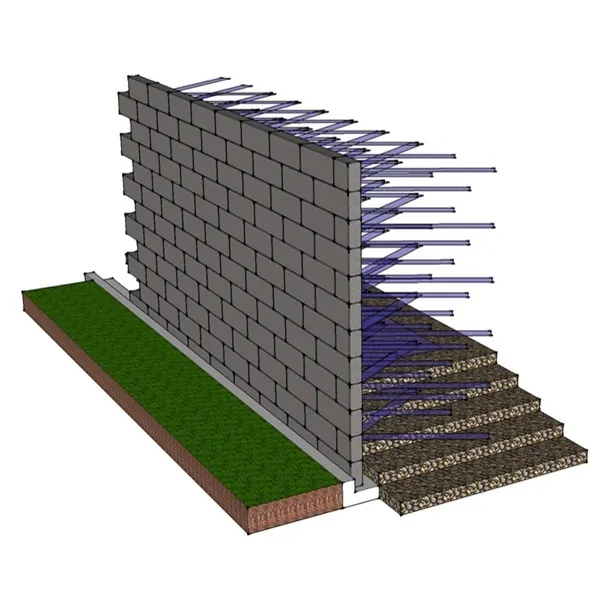

Facing elements

Reinforced Earth walls can be constructed with any of three major facing types: precast panels, wire facings and concrete masonry blocks. Since the facing is the only visible feature of a Reinforced Earth wall, selection of the right facing type, including size, shape, color and texture, is an important design decision.

Drainage elements

Drainage should be provided at the back of reinforcement zones to avoid the development of hydrostatic pressures during RE Wall construction. A drainage bay of a minimum 600 mm width at the back of the RE panel facing is usually used. Sometimes profiled blocks are also used as it has provision for placing granular drainage.

Leveling pads

Rubber, wooden or concrete bearing pads are used for horizontal joints so that there is no concrete contact between the panels and to avoid the chipping of concrete .

Filter cloth

Migration of backfill fines into the joints is prevented by wide strips of filter cloth glued over the joints on the back face of the wall.It is used for horizontal and vertical joints in the interior side of the panels such that the interior fill may not come out of the joints .

Design considerations for Reinforced Earth Wall

Check External/ Internal stability

To assess external stability check the stability of sliding, overturning, bearing/tilt and slip by considering the effects of dead loads, other loads and forces acting on the structure. To assess internal stability check out tension and pull out failure such as shear within the structure , arrangement and behavior of the reinforcement and backfill. Also checks the stability for each reinforcement layers and stability of wedges

Earth soil

A selected backfill must meet the minimum requirement for mechanical and electrochemical parameters, so that the required service life of the structure gets resistance to the flow of stray current.

Soil Reinforcement

According to the selected backfill and the structure’s service life, different types of reinforcements can be used in order to meet the specification required in the project.

Facing

The service life should be considered for the facing selection of the structures, you need to consider whether it will be permanent or temporary.

These factors need to be considered while selecting a reinforced earth wall for your projects.

Advantages of Reinforced Earth Wall

The geosys reinforced earth retaining wall not only protects your landscaping but it also contributes aesthetics value. Its advantages include;.

- Counteract the forces of gravity to protect the structure

- Holds the soil together for better functioning

- Resists Gravity Load

- Prevent sinkholes from destroying landscape structure

- Stabilizes the sloping landscapes

- Provides the level surfaces on slopes

- Compatible with a variety of decorative facing systems

- Reduces maintenance and prevents erosion

- Holds back the earth and maintain a difference in the height of the ground surface

- Withstand the grounds or backfill, other externally exerted loads transmit

- Provides stability under large and unforeseen deformations such as differential settlements and subsidence

- Can be used with a wide range of fill materials

- Effective in flood control

- Extremely low maintenance

- Inextensible soil reinforcements and bolted connections quickly installed

- Allow for a wide variety of surface textures and custom design

- Suitable and proven performance for extreme loading conditions

Applications Reinforced Earth Wall

Reinforced earth wall is compatible with a variety of facing systems, including large-sized discrete concrete panels, segmental panels, small-sized modular concrete blocks, vegetative facing with wrap around or with stones filled gabion, etc. It is also compatible with a wide range of fill materials, ranging from non-cohesive frictional fills locally available at site to fly ash and other similar non-cohesive, non-plastic fills. The marginal cohesive fill material can also be used with reinforced earth walls by providing adequate design. The benefits of these structures are especially evident on projects with challenging design conditions such as large structural loads, extreme height, restricted space, obstructions within the soil mass, poor foundation soils, high or variable water level and seismic loading. Its application area includes;

- Highway and roads

- Bridges

- Railway

- Waterways and dams

- Protective structures

- Commercial and public facilities

Conclusion

Given above are the different components, advantages and applications of Reinforced Earth Walls. When compared to conventional reinforced concrete walls are their ease of installation and quick construction. They do not require formwork or curing and each layer is structurally sound as it is laid, reducing the need for support, scaffolding or cranes.