Static charge is said to be created in a body or material by the accumulation of either positive or negative charge and is generally created when there is a relative movement between two materials. It is well-known that an insulative material such as plastic can hold this static charge for a long period while conductive material such as metals, when properly grounded can discharge this quickly.

Electrostatic discharge, when it happens, can cause significant injury, damage, and financial loss. In today’s world, the failure of components used in solid-state electronics, like integrated circuits, electronic components etc, can affect a large number of industries. Mobile phones, Laptops and Medical devices generate enormous amounts of data every day and can be an incredibly important resource in developing a humanitarian response. Failure of these important electronic devices can cause innumerable consequences in the modern world. This has been clearly understood by electronics-manufacturing and assembling companies and hence, created a fool-proof Electrostatic Protection Area (EPA).

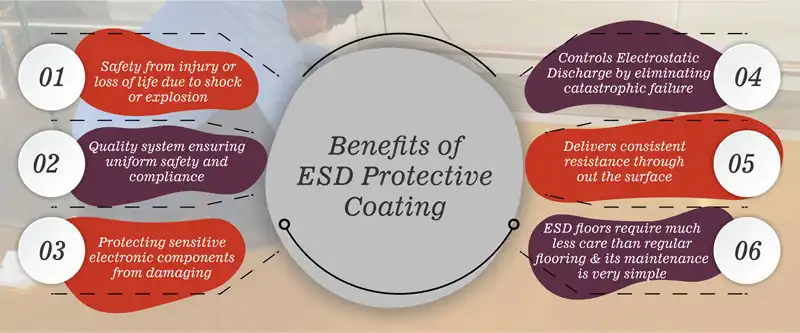

Electrostatic discharge floorings (ESD floorings) play a one-such important part that serves as a conduit for an electrical static discharge. The static charge that accumulates in the body when walking on an insulated floor of a plant that handles sensitive electronic equipment or potentially explosive chemicals can have devastating consequences. The selection of ESD floor coating, therefore, becomes pivotal. Neocrete Technologies, have understood the importance of ESD products and have developed an array of products to meet this growing demand.

Neocrete Technologies has launched a wide range of specialty ESD products for various applications to help you deal with the static electricity on various surfaces. Its “GroundBreaking” ESD coating products are manufactured to stay ahead of technological advancements in most of the electronic manufacturing and assembly units all over the world. Neocrete Technologies Pvt Ltd has created two groups of ESD products [Solvent – Borne & Water – Borne] for surface protection of various EPA including furniture, equipment, floors, walls and other surfaces. This strategy builds on decades of experience to foster a deliberate and holistic commitment to improve development of innovative products for the industry’s needs.

ESD protective coating products from Neocrete Technologies

In the electronic manufacturing and assembly industry a fool-proof ESD coating should meet ESD standards (ASTM F150, ANSI/ESD S 2020, IEC 61340-5-1). Discussed below are different ESD Coating products offered by Neocrete.

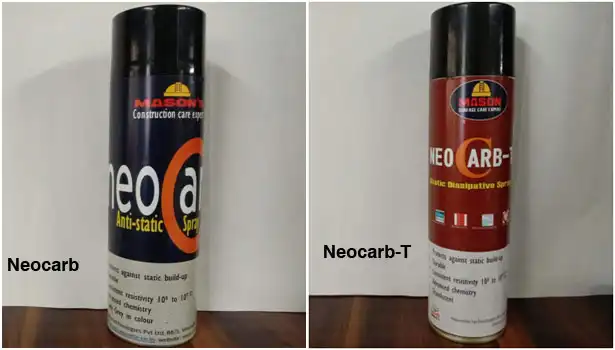

ESD Protective sprays

Neocarb is a single-component, solvented, static conductive spray. It provides a static protective coat over a variety of surfaces. It gives a dark-grey, uniform, matt surface nish.

Neocarb-T is a single-component, solvented, static dissipative acrylic spray to provide a static protective coat over a variety of surfaces. It gives a translucent, uniform and matt surface nish.

Features and benefits

- Protects against static build-up

- Durable

- Consistent surface resistivity reading

- Advanced Chemistry

Application areas

- Electronic assembly areas including ESD bins

- ESD trays & ESD workstations

- Partitions & cubicles

- Packaging for sensitive components

- Static protection for electronic components

- Shielding Room

ESD Protective paints (Solvent-borne)

Neocoat ASAC-C is a single-component, solvented, static conductive acrylic liquid to provide a static protective coat over a variety of surfaces. It gives a dark grey even surface nish. Neocoat ASAC-C can be coated by brush, roller or squeegee.

Neocoat ASAC-D is a single-component, solvented, static dissipative acrylic liquid to provide a static protective coat over a variety of surfaces. It gives a translucent even surface nish. Neocoat ASAC-D can be coated by brush, roller or squeegee.

Features and benefits

- Single component system and easy to apply

- UV and weather resistance

- Delivers consistent resistance through out the surface

- Few dark colours are available (ASAC-D is Translucent)

Application areas

- Work tables in electrical and electronic assembly areas

- Vertical surfaces In solvent handling areas

- Photographic areas and telecommunications industry

- Data centres and server rooms

- Contact surfaces in ordnance factories

- Wall panels and other insulative sheets to improve antistatic properties

ESD Protective paints (Water-borne)

Neoguard ASPAC-C is a single component, aqueous, pigmented, anti-static poly-acrylic coating. It can be painted or rolled onto any surface to provide conductive static protection to the coated surface. It is suitable to be applied over wood, concrete, cement sheets or MDF with suitable primers.

Neoguard ASPAC-D is a single component, aqueous, pigmented, anti-static poly-acrylic coating. It can be painted or rolled onto any surface to provide dissipative static protection to the coated surface. It is suitable to be applied over wood, concrete, cement sheets or MDF with suitable primers.

Features and benefits

- Single component, pigmented system and easy to apply

- UV and weather resistance

- Delivers consistent resistance through out the surface

- Limited range of colours are available

- Optional antimicrobial coatings for clean rooms ensures asy cleanability with antibacterial property

Application areas

- Work tables in electrical and electronic assembly areas

- Vertical surfaces In solvent handling areas

- Photographic areas and telecommunications industry

- Data centres and server rooms

- Contact surfaces in ordnance factories

- Wall panels and other insulative sheets to improve anti- static properties

- Floors subjected to foot traffic as well light material movements

Speciality ESD product

Neoguard ST-Clear is a technological marvel of a product. Its special formulation utilizes the superior properties of PU-acrylic polymers and conductive compounds to provide a crystal clear static-dissipative coating. It can be applied by brush, roller or squeegee onto wood, concrete, cement sheets or MDF with suitable primers. It can be diluted with water and applied over existing anti-static floors to rejuvenate the performance.

Features and benefits

- Single component system and easy to apply

- UV and weather resistance.

- Delivers consistent resistance through out the surface

Application areas

- Cleanrooms and hospitals

- Electronic manufacturing facilities

- Medical facilities

- Refurbishing or rejuvenating old anti-static tiles, antistatic vinyl sheets or anti-static carpets or even anti-static epoxy floors

Neocrete ESD protective coatings are made using the state of the art dispersion technology to make your floor conductive rather than surface conductive compared to traditional technologies.

For more details, visit- https://www.neocrete.co.in/product/esd-floorings/