Epoxy floor coatings are specialized, two-part mixture that consists of resin and a hardener to form a hard plastic coating. As it is mixed, it forms a chemical reaction that gives your floor distinct qualities. One of the most important qualities that this chemical reaction produces is new stability and endurance in the surface. This coating seals and cures the surface it is applied to, forming a firm bond. It is generally applied over concrete, wood, VCT, tile, or many other common industrial and commercial floors. Epoxy coating is chemically different from other coatings as it is composed of a mixture of hardeners and polymer resins. The epoxy resin and the hardener bond with each other and the floor when properly mixed. This chemical bond results in a stiff plastic material that is extremely durable and resistant to degradation. It is typically applied over concrete floors to provide a smooth, durable surface and increase the floor’s load-carrying capacity.

Advantages of Epoxy flooring coatings

- Durable And Resistant,

- Reduces Damage To Machinery

- Resistant To Chemicals

- Attractive Floor Surface

- Fast Application

- Easy To Clean

- Available in many different colors and designs.

- Seamless and water-tight

- Suitable for heavy use and mechanical loads

- Resistant to stains and water

- Durability

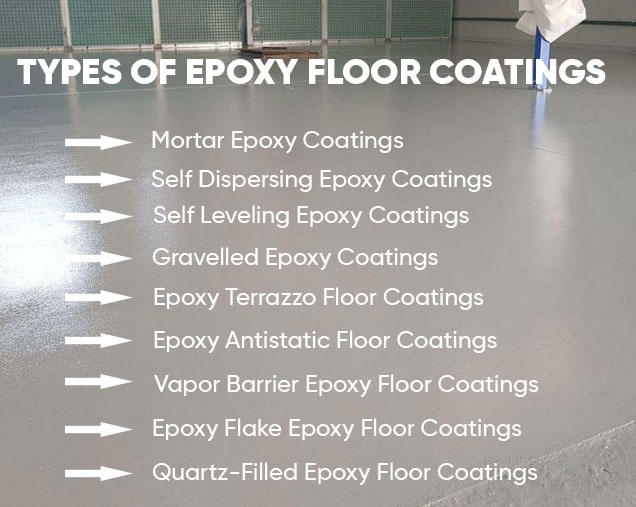

Types of Epoxy floor coatings

Whether you need flooring for an industrial plant, healthcare facility, manufacturing plant, school or university, food and agricultural facility, or other commercial industry, there are several types of epoxy flooring that can meet your needs. Discussed below are different types of epoxy floor coatings.

Mortar Epoxy Coatings – One of the strongest types of all epoxy floors. This type of epoxy coating is commonly used in heavy industry applications and can also be used to repair cracks before laying other types of epoxy floors. It comprises solid epoxies and graded or quartz sand. Mortar systems are ideal for spaces that require a floor that is highly chemically-resistant and can withstand a great deal of impact. This epoxy floor can be used to repair cracks before applying another type of epoxy floor.

Self Dispersing Epoxy Coatings – Commonly used in areas that receive frequent forklift or heavy truck traffic as it has very good mechanical strength. It can be mixed with quartz sand, which provides added durability. This type of epoxy coating is commonly used in food processing industries or other locations where liquids are present because it has good anti-slip characteristics.

Self Leveling Epoxy Coatings – It creates a very smooth surface that hides cracks or imperfections. It also offers a strong and aesthetically appealing floor. Self-leveling epoxy floors are often found in office buildings, showrooms, warehouses, and manufacturing plants. These are easy to install over new and old concrete floors as they level easily creating a seamless and smooth surface.

Gravelled Epoxy Coatings – Can be used for decorative and appealing options, gravelled epoxy floors offer colorful flakes that give the appearance of gravel. This can be an ideal option if you want a brand or logo on the floor. They can be used for adding logotypes, brand marks, and decorative details to floors.

Epoxy Terrazzo Floor Coatings – Composed variety of mixture of aggregate chips like stone or marble and either epoxy resin or concrete. It can be used both indoors and outdoors and can be poured as concrete or laid in tiles. These are normally used in large areas such as entrances and hallways in schools, office buildings, and commercial buildings.

Epoxy Antistatic Floor Coatings – Specialized epoxy coating is designed for use where static-sensitive electronic components are in permanent use. It prevents harmful electrical charge build-up from destroying sensitive components or parts by dissipating the charge safely to the ground. Anti-static flooring also known as Static Dissipative Flooring protects both sensitive electronic equipment and personnel from an electrostatic discharge (ESD). Antistatic resin flooring typically contains a conductive material that accumulates static electricity to dissipate any potential static discharge and needs to be grounded or earthed. These type of floor coatings can also help in preventing explosions and fires when working with flammable gases and liquid materials, helping to reduce the risk of costly damage to equipment and injury to personnel.

Vapor Barrier Epoxy Floor Coatings – Applied on top of concrete floors to give it an impenetrable surface that reduces vapor transmission to almost zero. This coating is normally added before the final flooring surface is added such as hardwood floors, carpet, tile, and sheet vinyl. When moisture management or zero vapor transmission is needed, a vapor barrier epoxy coating is the solution.

Epoxy Flake Epoxy Floor Coatings – Adding colorful flakes to the resin creates an aesthetically appealing effect. This type of flooring can be found in many industries, including medical facilities, commercial kitchens, and more. This type of flooring adds multicolored chips or flakes into the coating while it is wet to give it a decorative look when finished.

Quartz-Filled Epoxy Floor Coatings – It is a combination of a high-performance epoxy polymer resin and stained quartz grains. It can be used as a bonding agent, a decorative addition, or even to create an anti-slip surface. This type of epoxy flooring is often found in restrooms, schools, cafeterias, lobbies, offices, and showrooms.

Installation methods of Epoxy floor coating

- Preparing the floor surface

- Making it dust-free for new coat of epoxy coating on its top

- Fill all cracks, holes, and imperfections in the concrete with an epoxy patching material

- The next step includes grinding, shot blasting, and scarifying to have a course surface

- Patching and repairing all the major cracks identified on the floor

- The surface priming coat is applied to the floor

- Fill all the visible cracks and holes present on the floor with epoxy

- The epoxy hardener is mixed together with an epoxy resin and applied over the floor surface in multiple layers in the final stage

- After application, the epoxy floor is cured

- The curing process is initiated only when the epoxy begins a reaction with another curing agent.

*The steps might change a bit depending upon of substrate analysis and other factors.

Conclusion

Epoxy flooring is a versatile chemical solution that is practical, long-lasting, highly resistant to impact, and customizable for any space. Whether you need an elegant entrance to a restaurant or need an unyielding surface to withstand industrial work.If you have considered the advantages of epoxy floor coatings and are interested in this method for your garage or basement, a team of professionals can install your new protective and glossy surface. Discuss specifications in the epoxy floor coating style and design with seasoned professionals.