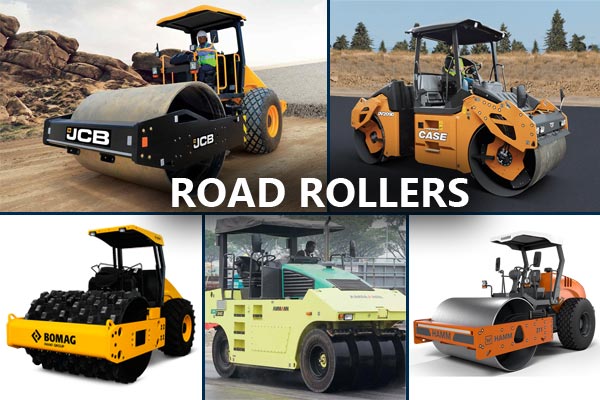

Road rollers are most often used for road construction or for creating compact foundations for large areas although they can also be used in areas as diverse as on landfill sites or agricultural projects. The primary use for road rollers is to crush, knead or vibrate loose materials by applying direct pressure. The rolling process is used to compact loosely bound foundation materials, so they remain compacted and do not come loose. There is the availability of different types of road rollers for different construction needs. Each of them is discussed below.

Different types of road rollers used in construction

Grid rollers

Grid rollers models have a cylindrical heavy steel surface comprising a network of steel bars that form a grid with square-shaped holes. It is common for the roller to be ballasted with concrete blocks. This type of roller is generally a towed unit and provides high contact pressure but minimal kneading action. They are typically used for the compaction of well-graded coarse soils and weathered rocks, often in subgrade and sub-base road projects. They are not suitable for clayey soils, silty clays or uniform soils.

Smooth wheeled rollers

These rollers come with one large steel drum in front and two steel drums in the rear. The gross weight of these rollers is in the range of 8-10 tonne. The other type of smooth wheel roller is called Tandem Roller, which weighs between 6-8 tonne. The weight of the roller can be increased up to 20 tonne by ballasting the inside space of the roller drums with either water ar wet sand. Steel sections are also loaded sometimes on double drum rollers mounted on a steel frame to which axles are attached. The performance of a smooth wheel roller depends upon its load per cm width and diameter of the roll. The load per cm width is derived from the gross weight of the drum. Smooth wheel rollers are useful for compaction when the material does not require great pressure. These are also used to finish the upper layers.

Pneumatic tyred rollers

Pneumatic Tyred Rollers provide the kneading and sealing effect that is so critical on job sites. The tyred rollers perform on both asphalt and aggregates, which of course means the machines must be flexible. They certainly are, with air pressure adjustments made without the operator ever leaving the cab. Ballast packages easily can be added or removed to ensure the most efficient machine and process are provided.

These types of rollers consist of tyres that provide better static penetration into the materials. The weight of the machines and the air pressure of the tires can be adjusted to meet the specific pressure desired on a particular job. In this regard. The adoption of Pneumatic Roller particularly in the construction of roads is very necessary to avoid timely road damages, potholes, road breakage as a result of poor construction of the roads.

Sheepsfoot rollers

Sheepsfoot rollers are of a static and vibration type machine, they are used for compaction of soil with a mixture of all fine-grained clay and sand-gravel. Modern models have metal drums with luggage fixing and can pressurize up to 14 kg / sq. cm. There are different types of lugs i.e. spindle-shaped wide base, prismatic and clubfoot type. The weight of the drum can be increased as in the case of rollers of smooth wheels with water, wet sand or by mounting sections of steel. For compacting heavy clays and silty clays, sheepsfoot rollers are found to be very effective. These rollers are employed in road and rail projects. Different types of lugs are namely spindle-shaped with widened base, prismatic and clubfoot type. A single drum required to be towed with a tractor or these can be mobile sheepsfoot rollers with tandem drums. Ballasting with water, wet sand or steel sections can increase the weight of these drums.

Single drum rollers

A single drum roller is a heavy-duty piece of machinery. The front has a giant drum while the back has special tires. These tires are sturdier and able to prevent most flats. You need these heavy-duty tires when you work on construction sites and roads. On the single drum roller, the driver sits in the middle section. Modern models offer three different configurations to meet every surface compaction needs. The choice of world-class components ensures a high level of performance and reliability. The reinforced front scraper, the robust 32 mm thick drum and the turbocharger with pre-cleaner are just some examples of the design-for-quality concept.

Double drum rollers

Modern double drum asphalt roller range features everything from the most compact equipment for repair jobs to large machines for the biggest sites. Vibration dampened platforms, swivel seats for better visibility, logically sorted controls and Roll Over Protective Structures (ROPS) all contribute to the maneuverability, operator ergonomics and safety.

Padfoot/ Tamping rollers

These rollers are similar to sheepsfoot rollers with lugs of larger area than sheepsfoot rollers. The static pad foot rollers are also called tamping rollers to have static weights in the range of 15 to 12 40 tonne and their static linear drum loads are between 30 and 80 kg/cm. On account of their larger production capacity, they are replacing sheepsfoot rollers. The degree of compaction achieved is more and there is more uniformity of density. They operate at high speeds and are capable of even breaking large lumps. The rollers with leveling blades have the capability of spreading the material. There are also self-propelled pad foot rollers weighing around 11.0 tonne or more and having a linear load of 30 kg/cm to 50 kg/cm. They can compact clay materials from 30 cm to 40 cm in thickness.

Vibratory Rollers

Vibratory Rollers are used to compact loose soil or asphalt and are primarily used for roads and highway construction. These machines also find application for ground compaction/stabilisation at construction sites. Nowadays companies manufacture 10 tons to 12 tons soil compactors and 3.5 tons and 9 tons tandem compactors with advanced features. used to compact loose soil or asphalt and are primarily used for roads and highway construction. These machines also find application for ground compaction/stabilisation at construction sites. We can now get 3.5 tons and 9 tons tandem compactors with advanced features.

Conclusion

Road rollers are essential for those thinking about maximizing their output. Choosing the one that fits the project criteria is the key. There is a tremendous amount of stress that is put on the system and it’s important to start with a reliable solution. With the help of a high-grade road roller, it becomes easier than ever before to make sure proper results are found.

Image Source: volvoce.com, ammann.com, casece.com, wirtgen-group.com, bomag.com, jcb.com, thecivilstructure.blogspot.com