A pothole can be defined as localized distress in a pavement resulting from the breakup of the asphalt surface and possibly the base course. The thawing and freezing cycles are one of the biggest reasons for potholes. You need to properly cure this with the right machine to repair these potholes. The advancements in the industry have led to the technological advancement of pothole repair machines. There is a variety of pothole repair available in the Indian market that makes it possible for any interested contractor to match the equipment to the amount of pothole repair work he expects to do. Fixing the patch right the first time and using the method that is right for your schedule budget and type of surface being addressed is pivotal. Discussed below are different types of pothole repairing machines. The selection of pothole machine type depends on the nature of soil terrain and atmospheric condition of each region.

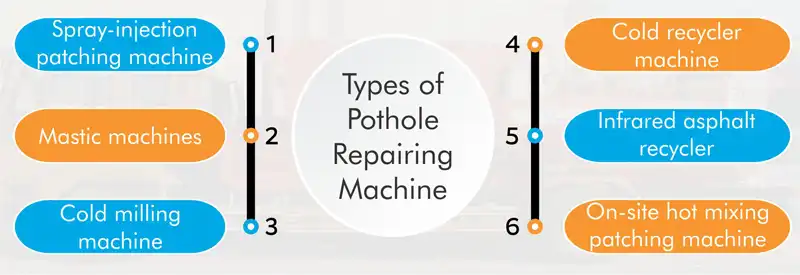

Types of Pothole Repairing Machine

Spray-injection patching machine

These are available in tow-behind, truck-mounted and standalone vehicles. The machine does the cleaning of the pothole using air pressure to blow water and debris from a pothole. The Durapatcher model P#3 is equipped with attachments mounted on track to enable shaping, chiseling removal of damaged asphalt, spray tack coat, spray inject mix, spray of dust and heavy duty compaction, With the machine you can cover 100 to 150 potholes per day with a minimum crew of 4. Spray patching is done with a HIGH VFM -pressure system, which delivers the necessary air, aggregate and emulsion. The air pressure removes water, dirt and any debris is removed from the pothole. Then the interior of the pothole is sprayed with a coat of liquid asphalt to help ensure a strong bond between the aggregate mix and existing asphalt. Modern models are equipped with dual aggregate hoppers to carry and distribute two different gradations of aggregate, allowing for more effective repair of different size potholes. The P#5 machine is more advanced and comes with joystick control providing full operator control from the truck cab or the ground with a remote-control system. Manual control units provide significant savings while offering full operator control from the ground in front of the truck. This feature also allows the working boom to be mounted on an existing fleet chassis with no need for special chassis configurations. Spray injection patching machines use an air-driven system to deliver emulsion and aggregate to the road. The nozzle provides emulsion-coated aggregate with the right amount of emulsion regardless of aggregate size. It can be used to repair bigger as well as smaller potholes in roads, highways, bridges, or parking areas.

Mastic machines C# 1 Multipurpose Portable Mastic plant and Pothole Machine

These machines use mastic as an aggregate and a binder. Mastic in terms of pavement preservation is used as a patching material made of polymer modified asphalts (sealants) and aggregate. The machines use locally source specified stone aggregate and polymer-modified asphalts to make a polymer-modified stone matrix patch. It is designed to heat 24,000-lb of mastic material in an 8-hour shift. This machine enables mastic production on-site and on-demand. The machine uses a correct fitted binder that produces aggregate at the correct temperature. It heats the aggregate and binder (sealant) and then it can be used for proportional mixed design as per the need of the project. The operator is in control of this; he can set volumes and material proportions as per the need. The machine utilizes a minimum of moving parts in the delivery system. The mix on demand is the biggest advantage of this machine. It can be used for repairing big patches on roads and highways.

Cold milling machine

These machines are especially suitable for the maintenance and construction of city roads and highways. They are used for the quick, highly efficient removal of asphalt and concrete pavements. In doing so, they create an even, true-to-profile base for the construction of new surface courses of uniform layer thickness. They are equipped with wheel units and are used for working small areas and for high-precision milling in extremely restricted space conditions. With four-wheel drive, small size and large milling depth make it ideal for the rural, state and national highways. Large steering ensures a small turning radius and flexible steering. The four rounds of the whole automatic machine have a significant increase in the braking effect of the whole machine, to ensure safety. The right leg rotation way meets the narrow welt milling construction requirements. The machines are equipped with a wheeled chassis and a milling drum positioned at the rear. The granulated RAP which is broken up by the rotating milling drum is transferred to a slewing and height-adjustable discharge conveyor and immediately loaded onto waiting transport vehicles. The compact rear loaders are highly maneuverable and their rear right wheel can be swiveled in when milling flush to the edges of obstacles. It is used to patch bigger potholes for rural roads as well as highways.

Cold recycler machine

These machines are used for cold recycled paving of patches that add on cement, emulsion and foamed bitumen. It comes with a working width of 7 ft. 10 in. (2.40 m) and a maximum working depth of 20.1 in. (510 mm), the recycler is highly flexible when it comes to operations in soil stabilising and cold recycling. The levels in milling and mixing and its variable mixing chamber is consistent. For cold recycling, the ideal performance range is up to 10,000 ft² per hour and 5.9 to 7.9 in. of asphalt thickness. It is equipped with the milling and mixing rotor, which thoroughly mixes the damaged layers i.e. the asphalt surface course as well as the binder and base courses, together with the pre-spread cement and added water in a variable mixing chamber and then redeposited the material. Different gears options for working speed, designed for difficult working conditions of roads, gears options for travel speed are also available for different travel demands between job sites and different job working conditions. Machine output has been optimized by powerful motorization with high torque reserves while engine power is transmitted directly and effectively, benefiting its milling performance. Different rotor speeds guarantee optimum mixing performance, aided also by ultramodern computer-controlled metering technology with automatic monitoring to ensure exactly the right mix. These machines can be used for a wide range of application starting from small to big patches,

Infrared asphalt recycler

Infrared asphalt recyclers correct pothole defects by recycling the existing bitumen giving you a permanent and seamless surface repair. There is no wastage of asphalt on the road because the existing asphalt is recycled by this technology making it a green economical process. There is no wastage of asphalt on the road because the existing asphalt is recycled by this technology making it a green economical process with no debris left after the work. With infrared road surface maintenance technology, road potholes can be easily fixed in a lesser time. By lifting the hopper, the dump box makes offloading asphalt easy. To ensure stability when the hopper is raised, each dump box is built on a tandem axle trailer frame that cradles a lowered hopper using body guides to keep it centered. Dump box trailers are constructed with two hydraulic cylinders that raise the hopper and prevent twisting from an uneven load. With this design, each cylinder acts as a safety backup for the other. The latest model combines the highest heat transfer method with whole-batch mixing and proprietary rejuvenators to produce asphalt with high-level elasticity. The machine is used for repair of bigger patches in highways.

On-site hot mixing patching machine

This mix is poured into the cracks and potholes on the surface and heavy rollers are used to smooth the surface. The machine comes fitted to the discharge end of the drying cylinder, with a fuel pump for feeding fuel and an air blower for supplying air. These machines can use the milled material as well as new aggregate and bitumen. Only the required amount is to be Hot-Mixed fresh (no wastage) and very useful where long distances of road or Highways are to be maintained.