The facade combines attributes of both appearance as well as superior performance in a manner, unlike any other building system. It is often the most important aspect from a design standpoint, as it sets the tone for the rest of the building. The term ‘façade’ can refer to any predominantly vertical face of a building envelope, such as an external wall. Sometimes the term ‘façade’ is used to refer more specifically to external faces of buildings that have particular architectural emphasis, such as an imposing design, decoration, the main entrance to the building and so on. Given below are different types of facades for building structures.

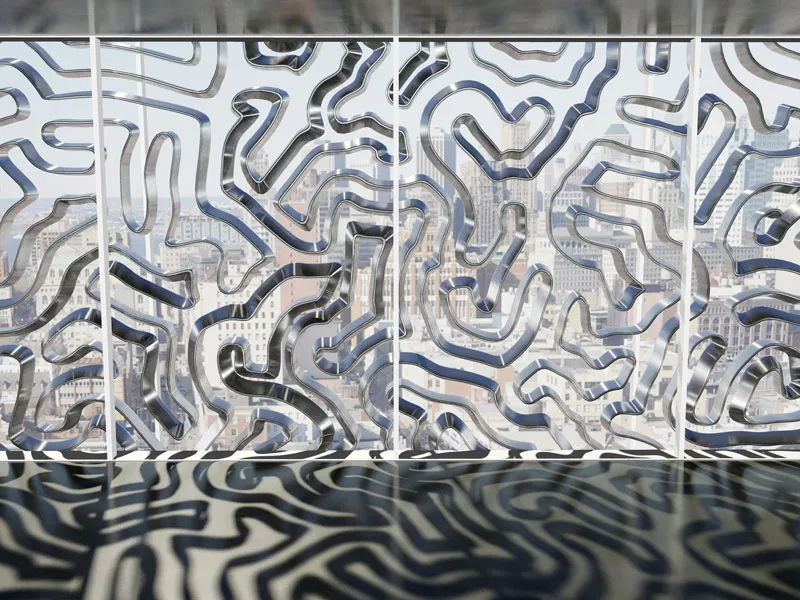

Steel facade

A variety of steel components may be used in modern facade systems, such as Steel profiled sheets and composite (sandwich) panels, Flat and rigidized cassette panels with folded edges, Light steel infill walls, Hollow steel sections, Stainless steel glazing support systems, to name a few.

Panel frame facade

Panel facades are framed by mullions on the vertical edges and transoms on the horizontal edges. Mullions and transoms are thermally broken to prevent cold bridging through the element so that condensation does not occur. Unitized curtain walling is identifiable by the presence of split mullions and transoms on the panel perimeters. These structural shapes are cheap to manufacture in large quantities once a die has been made.

Curtain Walling facade

Curtain walling is the generic name given to metallic lightweight cladding or glazed cladding systems that are directly supported by a structural frame. In some cases, a stone veneer or large tiled fascia may be attached to give the appearance of a more monolithic cladding system.

Clay facade

Clay facades are nothing but the panels made of terracotta that can be cladded on the exterior walls or facade of any building. Though glass and aluminium based facades have been recent additions to Indian cityscapes, borrowed largely from the west, but clay facades like facing bricks or clay facade tiles have been in use for many years. Clay facades are the outcome of sophisticated technology and advanced firing processes and hence are highly resistant to the exterior environment. When compared to paint, which can look smudged with dust and dirt, clay facades, retain the colour for a longer period of time. Since they are made of terracotta. Their weather resistance power makes them highly durable which last for decades.

Steel and glass facade

Steel and glass are synergistic materials and are often used in facades and roofs of multi-storey buildings. The glass panels are generally supported by separate vertical steel elements to the main structural frame of the building that may be internal or external to the building. Stainless steel and hollow steel sections are often used in combination with glass.

Double-skin facade

This is formed of two glass walls separated by a cavity on south-facing elevations and are used to reduce the energy consumption of a building. Shading devices are usually mounted in the cavity and, depending on its width, walkways for access and cleaning. This type of façade has many variations in the arrangement. The two skins form a thermal buffer zone and passive solar gains in the cavity reduce heat losses in winter. If the cavity ventilation is integrated with the building services, air heated by the sun can be introduced into the building, providing good natural ventilation and reducing the heating load and vice versa during summer.

Aluminum Composite facade

Aluminum Composite Panel Cladding (ACP) is a widely-used term, describing flat panels that consist of thermoplastic core bonds between two aluminum sheets. ACPs are frequently used for external cladding of buildings (building facades). The main advantage of ACP is that it is very rigid and strong, despite its lightweight. Due to the ability to paint the aluminum in any color, ACPs are produced in a wide range of metallic and non-metallic colors as well as patterns that imitate other materials, such as wood or marble. Applications of ACPs are not limited to the building’s external cladding; they can be used in any cladding application, partitions, false ceilings etc.

Solar shading facade

Solar shading facade is a form of solar control that can be used to optimise the amount of solar heat gain and visible light that is admitted into a building. This can have a significant impact on the energy use of a building as well as on the thermal and visual comfort of occupants, protecting against overheating and glare on hot or sunny days. There is a wide variety of solar shading systems that may be used and incorporated as part of the building façade. There are: oval shaped horizontal steel elements that span horizontally between external columns and their size and spacing is designed to reduce the intensity of solar gain.

Glazing facade

Modern glazing facades are made of attachments to 2 or 4 separate glass panels using stainless steel brackets, also known as ‘spiders’ because of their multiple legs. The attachments to the glass panels are generally made by stainless steel brackets with neoprene gaskets through the glass, as shown below. These attachments permit articulation due to thermal and structural movements so that local stresses on the glass are minimised.

Insulated wall facade

Insulated wall facades are interlocking, composite metal-faced sandwich panels or concrete panels with insulation between internal and external concrete elements. Steel-faced insulated panels are frequently used on single storey and low-rise industrial buildings. Panels are usually designed to span one-way (either vertically or horizontally) and are made to suit commonly-used frame spacings without intermediate supports. Various insulation materials are available such as expanded polyurethane (PUR), polyisocyanurate (PIR) and mineral fibre with a range of insulating, fire-resisting and other physical properties.

Homeostatic façade

Homeostatic façade consists of an engineered ribbon, inside the cavity of a double-skin glass façade. The ribbon is made of dielectric elastomers: polymer materials that can be polarized by applying an electrical current. These materials are also flexible and consume very little power. Both sides of the dielectric material are coated with silver electrodes. This silver layer reflects light, and also distributes electrical charge across the material, causing it to deform. This helps the façade to regulate temperature inside the building.

Conclusion

In conclusion, the facade of a building plays a critical role in both its aesthetic appeal and functional performance. From the robust and versatile steel facade to the environmentally friendly clay facade, and from the advanced double-skin facade to the high-performing aluminum composite facade, each type offers unique benefits and characteristics. Additionally, the incorporation of advanced materials and technologies, such as homeostatic facades, showcases the potential for innovative solutions in modern architecture. For a cohesive and well-integrated design, it’s essential to consider not only the facade but also the interior elements like office furniture, ensuring a harmonious balance between functionality and aesthetics throughout the entire building.

Image Source: trendhunter.com, ductal.com, archello.com, pinterest.com, archilovers.com, wikipedia.org, 24greenbuildings.com, cmeventos.net, alutech-group.com, kingspanjindal.com, buildingcentre.co.uk, casalgrandepadana.com, materialdistrict.com