Distress occurs in concrete structures due to a lack of preventive measures which impacts the natural deterioration of a structure. It is more common now as structures are getting exposed to extreme environmental hazards. There are numerous well-known factors that cause premature distress in concrete structures. Each of them is explained below

Longitudinal distress in a concrete structure

Longitudinal distress occurs parallel to the centerline of the pavement. They can be caused by a poorly constructed joint; shrinkage of the asphalt layer; cracks reflecting up from an underlying layer; and longitudinal segregation due to improper paver operation. Longitudinal distress is parallel to the pavement’s centerline or lay down direction. They may be caused by (1) a poorly constructed paving lane joint, (2) shrinkage of the AC surface due to low temperatures or hardening of the asphalt, or (3) a reflective crack caused by cracks beneath the surface course, including cracks in PCC slabs (but not at PCC joints).

Corner curling distress in a concrete structure

Corner Curling distress is usually caused by unequal drying shrinkage: It’s greater at the top of the slab than at the bottom. This causes the corners to curl upward, leaving them unsupported. Traffic loads then cause corner cracks like those that have occurred at nearly every contraction-joint intersection (see drawing, above). The multiple cracking in some of the panels may be caused by restrained drying shrinkage or thermal contraction.

D-cracking distress in a concrete structure

D-cracking distress in concrete is caused by freeze-thaw cycles deteriorating the aggregate in concrete. Water naturally accumulates at the base and sub-base layers under concrete. When this water suffers from freeze-thaw cycles it wears on the durability of the concrete and begins to crack in the aggregate at the base of the concrete working its way to the surface. Since the cracking begins beneath the surface it is hard to detect D-Cracking before it becomes visible on the surface of the pavement.

Joint seal distress in a concrete structure

Joint seal damage is any condition which enables incompressible materials or water to infiltrate the joint from the surface. Typical types of joint seal damage are, Extrusion, hardening, adhesive failure (bonding), cohesive failure (splitting), or complete loss of sealant. The pavement joint- and crack-sealing faces several challenges as the new millennium approaches. These challenges cover a broad spectrum of issues, from materials to construction practices.

Shattered slab distress in a concrete structure

Intersecting cracks are cracks that break the slab into four or more pieces due to overloading or inadequate support, or both. The high-severity level of this distress type, as defined as follows, is referred to as a shattered slab. In this type of distress,the slab is broken into four or five pieces with over 15% of the cracks of medium severity slab broken into six or more pieces with over 85% of the cracks of low severity.

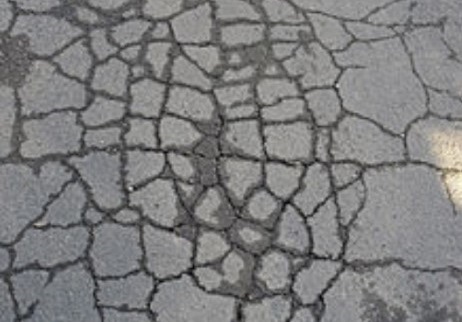

Crazing distress in a concrete structure

Crazing distress is a pattern of random fine cracks that occur at the surface of the concrete at an early age when the unhardened surface mortar dries out faster than the concrete below. This drying at the surface causes the concrete at the surface to shrink at a faster rate than the concrete below causing stresses at the surface resulting in the fine “map crack” pattern. Since these cracks occur at the surface only, they become an unpleasant sight but are none-the-less harmless structurally and will not cause durability problems. Crazing may be more evident when slabs are constructed in hot, windy, and dry installation conditions.

Blowup distress in a concrete structure

Blowup distress occurs in hot weather, usually at a transverse crack or joint that is not wide enough to permit expansion by the concrete slabs. The insufficient width is usually caused by the infiltration of incompressible materials into the joint space. When expansion cannot relieve enough pressure, a localized upward movement of the slab edges (buckling) or shattering will occur in the vicinity of the joint. Blowups can also occur at utility cuts and drainage inlets

Spalling distress in a concrete structure

There are many causes of concrete spalling distress, which include the improper placement of concrete and its reinforcing, electrochemical (galvanic) reactions between embedded metals within the concrete matrix, and corrosion of embedded reinforcing steel due to exposure to water and/or chemicals. This article will address concrete spalling as a result of corrosion of its steel reinforcing and how concrete placement and its exposure can affect the corrosion process.

Distortion distress in a concrete structure

Distortion distress occurs when there is a severe weakness in the subgrade of your concrete pavement that causes it to shift before it has properly set. The movement usually takes place after construction has ended. It’s often the result of shoddy workmanship combined with the harsh effects of natural elements and the physical pressures of being in a high-traffic area.

Pumping distress in a concrete structure

Pumping distress occurs due to the movement of material underneath the slab or ejection of material from underneath the slab as a result of water pressure. Water accumulated underneath a PCC slab will pressurize when the slab deflects under load. This can be caused by such things as a high water table, poor drainage, and panel cracks or poor joint seals that allow water to infiltrate the underlying material.

Alkali aggregate reaction distress in a concrete structure

Many siliceous igneous (opal, chalcedony) and sedimentary rocks (chert) possess a glassy or amorphous texture. In alkaline environments, the silica structure can get dissolved from these aggregates. The resultant reaction between silica and alkalis results in the formation of a gel that is expansive. This phenomenon is called the alkali-silica reaction. Strained quartz present in metamorphic rocks may also be susceptible to damage by alkali-silica reaction (ASR).

Corrosion distress in a concrete structure

Corrosion distress in concrete members occurs with age due to corrosion in reinforcement, loading, settlement of foundations, etc. This distress in a building can be found by the development of cracks in concrete members such as slabs, beams, columns, etc. The corrosion of steel reinforcement in concrete is complex, but basically, it is an electrochemical reaction similar to that of a simple battery. The composition of mild steel varies along its length and potential anodic (more negatively charged) and cathodic (positively charged) sites can be set up at various points.

Structural distress in a concrete structure

Structural distress can be caused by a variety of factors, the most common being the corrosion of the embedded reinforcing steel. Because steel corrodes when exposed to moisture and oxygen, preventing that exposure is critical. Pure concrete possesses natural corrosion-inhibiting properties due to its high alkalinity. Provided the concrete is maintained in this high alkaline environment, the steel will not corrode. The protection is lost, however, if the alkalinity of the concrete is lowered due to some external factor affecting the pH of the concrete and destroying the protective layer to a level which will allow the corrosion process to begin.

Conclusion

Adequate measures of repair and rehabilitation need to be undertaken to address these distress in a concrete structure. Diligent knowledge and expert advice for carrying out necessary techniques needed.

Image Source: ascelibrary.org, pavementinteractive.org, parchem.com.au, fprimec.com, acrp-pavement-tool.tti.tamu.edu, in.gov, myrenovationspecialist.com, terracon.com, hesspumice.com,