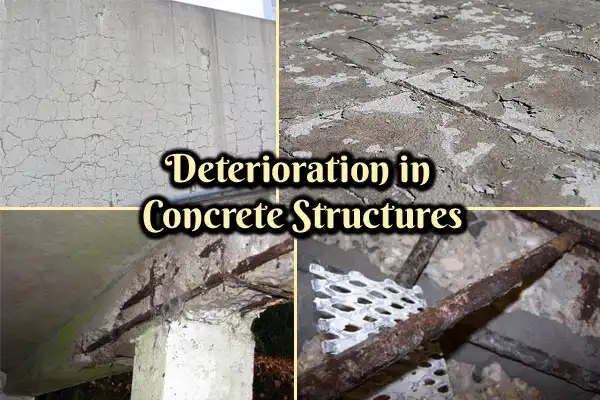

Deterioration in concrete structure is a frequently discussed topic. It can be the result of one or a combination of factors, such as drying shrinkage, thermal contraction, restraint (external or internal) to shortening, subgrade settlement, and applied loads. Concrete can deteriorate for a variety of reasons, and concrete damage is often the result of a combination of factors. The primitive factors are, Distress in concrete, Permeability of concrete and Aggressive deterioration agents. There are different types of causes under these three main divisions that cause deterioration, each of them is explained below. Physical and Chemical processes can impact durability and structural performance of the concrete. Defects in design, materials, workmanship, curing and maintenance can all impact the service life, safety and reliability of an element. In this article, we will review some of the most common types of deterioration mechanisms in concrete.

Different types of Deterioration in Concrete Structures

Corrosion of Embedded Metals in concrete

When steel corrodes, the resulting rust occupies a greater volume than the steel. This expansion creates tensile stresses in the concrete, which can eventually cause cracking, delamination, and spalling. Steel corrodes because it is not a naturally occurring material. Rather, iron ore is smelted and refined to produce steel. The production steps that transform iron ore into steel add energy to the metal. The corrosion of structural steel is an electrochemical process that requires the simultaneous presence of moisture and oxygen. Essentially, the iron in the steel is oxidised to produce rust, which occupies a greater volume than the steel.

Freeze thaw deterioration in concrete

Freeze-thaw damage is a potentially serious deterioration process that occurs in concrete structures in cold climates. Premature damage to concrete slabs during freezing and thawing cycles represents a major challenge to pavement durability and resilience. When water freezes, it expands about 9%. As the water in moist concrete freezes, it produces pressure in the capillaries and pores of the concrete. If the pressure exceeds the tensile strength of the concrete, the cavity will dilate and rupture. The accumulative effect of successive freeze-thaw cycles and disruption of paste and aggregate can eventually cause significant expansion and cracking, scaling, and crumbling of the concrete Freeze/thaw damage occurs in concrete when the water molecules in concrete freeze and expand beyond the volume constraints of the concrete.

Chemical attack in concrete

Chemical attack is one of the more common causes of deterioration of concrete in industry today. Animal fats, natural and artificial oils, acids, alkalis, and various industrial salts are all damaging to concrete. Chemical attack occurs due to pollution products and following discharge activity on the insulator surface. Examination of field-aged insulators has found formation of uniform thin pollution layers on the surface. A chemical attack involves dissolution of substances or chemical reactions between substances and components of the concrete. Reaction products might cause problems, due to dissolution or expansion.

Alkali-Aggregate Reactivity in concrete

Alkali-aggregate reactions can be either alkali-carbonate reactions (ACRs) or alkali-silica reactions (ASRs). In ACR, the reaction is between the alkalies (sodium and potassium) and certain carbonate rocks, particularly calcitic dolomite and dolomitic limestones, present in some aggregates. It is a deleterious swelling reaction that occurs over time in concrete between the highly alkaline cement paste and the reactive amorphous (i.e., non-crystalline) silica found in many common aggregates, given sufficient moisture. This deleterious chemical reaction causes the expansion of the altered aggregate by the formation of a soluble and viscous gel of sodium silicate. This hygroscopic gel swells and increases in volume when absorbing water: it exerts an expansive pressure inside the siliceous aggregate, causing spalling and loss of strength of the concrete, finally leading to its failure.

Abrasion Erosion in concrete

The abrasion damage caused by the grinding action of silt, sand, and rock. The grinding action will remove the concrete surface and expose the aggregates in some cases. Hydraulic concrete structures frequently experience long-term abrasive erosion by water-borne sand, resulting in surface damage, eventually limiting their service life. Abrasion damage occurs when the surface of concrete is unable to resist wear caused by rubbing and friction. As the outer paste of concrete wears, the fine and coarse aggregate are exposed and abrasion and impact will cause additional degradation that is related to aggregate-to-paste bond strength and hardness of the aggregate.

Plastic Shrinkage in concrete

Loss of water from fresh concrete, which leads to plastic shrinkage, can occur in a couple of ways. The predominant mode is, however, through evaporation from an exposed surface. Concrete can also lose water through suction by the subbase or, depending on the type of material used in its manufacture, the formwork. Such loss of water can aggravate the effects of surface evaporation. It is generally accepted that the loss of water from the paste fraction of concrete due to external factors generates negative capillary pressures that cause the volume of the paste to contract, hence the shrinkage. The rate of water evaporation is usually aggravated by a combination of high wind speed, low relative humidity, and high ambient and concrete temperatures.

Drying Shrinkage in concrete

The loss of moisture from concrete after it hardens, and hence drying shrinkage, is inevitable unless the concrete is completely submerged in water or is in an environment with 100 percent relative humidity. Thus, drying shrinkage is a phenomenon that routinely occurs and merits careful consideration in the design and construction of concrete structures. The actual mechanisms by which drying shrinkage occurs are complex, but it is generally agreed upon that they involve the loss of adsorbed water from the hydrated cement paste.When concrete is initially exposed to a drying condition – one in which there is a difference between the relative humidity of the environment and that of the concrete – it first loses free water. In the larger capillary pores this results in little or no shrinkage. In the finer water-filled capillary pores (2.5 to 50 nm size) due to loss of moisture, curved menisci are formed, and the surface tension of water pulls the walls of the pores

Overload impact in concrete

Overload damage can occur during construction when concrete has not yet reached design strength. Early removal of formwork or the storage of heavy materials or operation of equipment on and around the structure can result in the overloading of certain concrete members. A common error occurs when precast members are not properly supported during transport and erection. Errors in post-tensioned construction, such as improperly timed or or sequenced strand release, can also cause overload cracking.

Patch Accelerated Corrosion in concrete

Commonly referred to as “ring anode corrosion” or “halo effect”, patch accelerated corrosion is a phenomenon specific to concrete restoration projects. When repairs are completed on corrosion-damaged structures, abrupt changes in the concrete surrounding the reinforcing steel are created. Typical concrete repair procedures call for removal of the concrete around the full circumference of the reinforcing steel within the repair area, cleaning of corrosion by-products from the steel, and refilling the cavity with new chloride-free, high pH concrete. This procedure leaves the reinforcing steel embedded in adjacent environments with abruptly different corrosion potentials. This difference in corrosion potential (voltage) is the driving force for new corrosion sites to form in the surrounding contaminated concrete. The evidence of this activity is the presence of new concrete spalling adjacent to previously completed patch repairs.

Conclusion

Deterioration of concrete structures can become a challenge for the owners of the structures. It is important to identify these defects on time, and plan appropriate repair strategies.

Image Source: pintrest.com, concretedecor.net, researchgate.net, reddit.com, cement.org, concrete.org.uk, myrenovationspecialist.com,