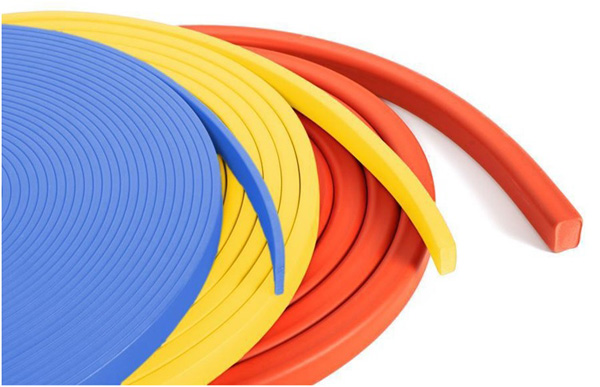

Pronil ACR is a new generation high performance acrylic polymer based expanding tape. It expands up to 900% when in contact with water. In a totally dry state, it will shrink to its original installation dimension and re-expand on wetting. It is used in concrete construction for the sealing of construction joints including wall to base connections, pipe entry systems, sealing of openings and interface sections between existing and new concrete. The range of Pronil ACR products is easily stored in it’s original moisture-proof wrap in cool, dry conditions away from sunlight. Discussed below are the advantages of joint treatment with Ponil ACR 300 (Acrylic Swellable Bar) and its application methods.

JOINT TREATMENT USING ACR300 (ACRYLIC SWELLABLE BAR)

Construction joints at the retaining wall shall be installed with ACR300; 20mm x 10mm cross-sectional sized hydro-swelling water bar based on advanced acrylic polymers. The water bar shall be formulated to exhibit low premature swelling (less than 100% within 12 hours) and shall not be based on super absorbents. The water bar shall be installed with special adhesive. (All Construction Chemical Manufacturers have adhesives to fix the ACR300)

Installation of ACR300 in Construction Joints

Substrate preparation:

Before starting to install the specified construction joint system, thesubstrate shall be jointly inspected by the Contractor and the Specialist Applicator for soundness; any defects shall first be repaired utilising products and systems compatible with the specified construction joint system. The substrate should be free from Loose particles, dust, Laitance etc…

- ACR300 hydrophilic acrylate based water bar shall be placed in all construction joints as protection to the water entry.

- The concrete substrate to which the ACR300 is to be fixed must be smooth and sound.

- Cut the ACR300 to the required length.

- Fix the ACR300 to the concrete substrate using any compatible Adhesive. Apply light tension to the ACR300 as it is being fixed.

- Allow the adhesive on the verticals to dry at least overnight before concreting.

- Protect the fixed ACR300 from mould release oil and dirt.

- Do not saturate the water bar before concreting as this may cause it to swell.

- After placement of the ACR300, cast the next concrete pour.

- If the surface of the concrete is smooth and clean, PRONIL Developed a Self-Adhesive made Acrylic Swellable Bar ACR300.

- Just remove the release liner and fix it on the smooth concrete surface. This self-Adhesive present in the ACR300 will fix to the concrete substrate.

ACR-300 (Self-Adhesive option available):

| Base | Acrylic Polymer |

| Tap water, wet/dry difference | ≥300% |

| Concrete water (14 days) | ≥200% |

| salt water (14 days) | ≥100% |

| Water pressure resistance (14 days) | 7 bar |

| Color | Red |

| Elongation at Break | 600% |

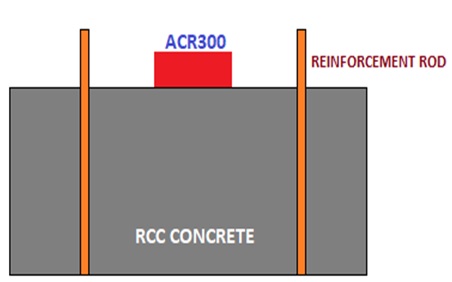

Schematic Diagram:

Shape of ACR300 – Before water comes in contact @ dry state. (Initial Stage)

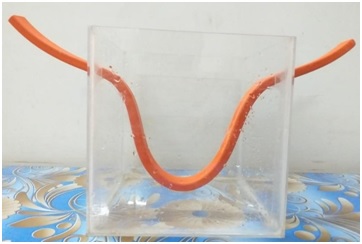

Shape of ACR300 – After water comes in contact @ Wet state. (12 Hours)

Shape of ACR300 – After removal of Water @ Dry state (After 24 Hours)

This is a BBA Certified Product

PRONIL specializes in manufacturing high-performance Acrylic Swellable Bars, Bentonite Hydrophilic Waterstops and Expansion Joint Tapes for construction for two decades. Apart from PROFLEX 3 they also have a wide range of Expansion Joint tapes and Waterproofing flexible Joint sealing tapes. To know more about the product range, visit:- www.pronil.com, or contact – +91 9489058644