A concrete pump is a machine used for transferring liquid concrete by pumping. There are two types of concrete pumps. Concrete pumps are an important part of any construction project because they are extensively used in transferring liquid concrete by pumping it to the job site. A concrete pump is controlled by a skilled concrete pump operator. The pump operator controls the operation, position, and output of the pump by directing the boom or hose. The operator is also in charge of driving the pump to the job site, setting up the pump, cleaning the pump after use, and making any necessary repairs.

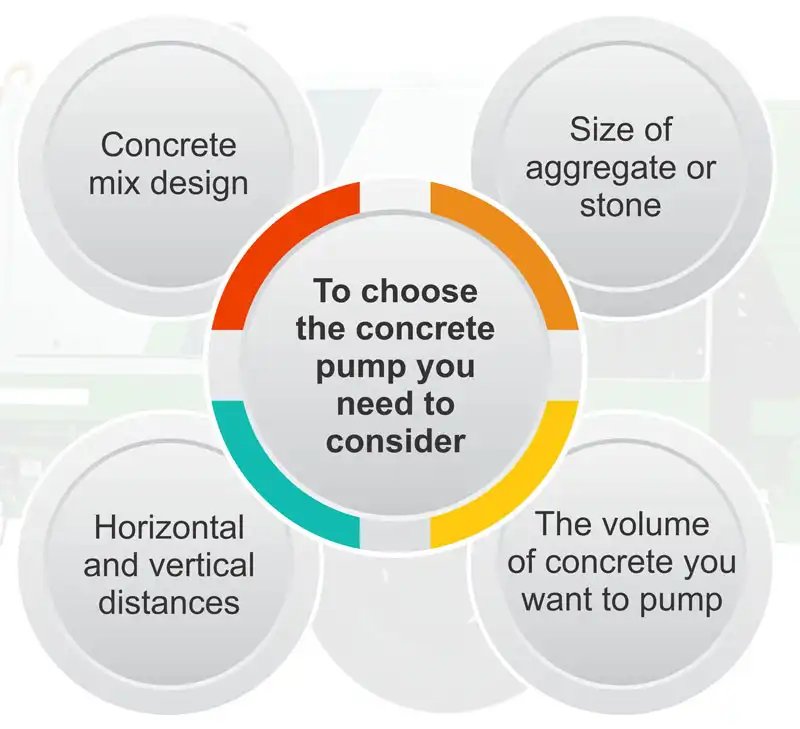

The Concrete pumps are one of the most efficient and cost-effective equipment for concrete placement that we have in present times. The different types of concrete pumps used for diverse construction projects are cost-effective. During construction projects, it is very crucial to choose the right concrete pumps that are economical, efficient and one that is specifically designed for your particular construction project.

Advantages and selection criterion of concrete pumps

Specialized machines like concrete pumps work to help you maximize your time. Versatile concrete pumping services save you valuable time and effort, allowing you to pour concrete in even the hardest-to-reach locations. Given below are a few of its advantages.

Trends in concrete pumps

Concrete pumps are undergoing advancements from more robust designs to enhanced digitization with IoT for predictive maintenance, to cater to higher mechanization, so that they can meet multiple application requirements. The placement of concrete in inaccessible areas has necessitated the use of pumps in the current construction process. Especially with the growth of ready-mixed concrete across the world, the need for pumping has increased manifold. An increase in infrastructural investments is one of the key drivers of the global concrete pumps market. Rapid urbanization across the country is the other crucial factor that boosts the demand for concrete pumps.

The new updated models come with a high-pressure pump that caters to concrete pumping to 80~100m building heights. The models are equipped with the latest S-valve technology and with highly wear-resistant steel components. The new product range covers numerous applications starting with the small, versatile concrete pump and ending with the concrete pump that has the highest reach and best maneuverability. There are requirements of pumps that can generate more pressure and thereby deliver more volume. To enhance higher productivity and compose the homogenous output mix, concrete pumps are now designed in a compact size that eases mobility and is apt for a user – friendly functioning.

Different types of concrete pumps

Boom or truck-mounted concrete pump

These used machines on large projects are Boom Pumps, especially where you need to place concrete in hard-to-reach locations. The latest models of concrete pumps can be mounted on 3 axle trucks with a placing boom with a Roll fold system. They come with around a 36-meter boom with X outriggers that offer more spaces for accessories storage. There are optional features like pump kits, Concrete stop valves and Automatic lighting systems. The new product range covers numerous applications starting with the small, versatile concrete pump and ending with the concrete pump that has the highest reach and best maneuverability. The machines can take high delivery pressures up to 130 bars for delivery outputs of up to 200m³/h. The new series machines come mounted on a truck chassis of your choice. It is also possible to customize your setup to include storage for all your pipework and other accessories so you’ve always got everything you need in the one mobile package.

Trailer line/stationary concrete pump

These are used in applications that require smaller volume pumping such as swimming pools, sidewalks, and small homes concrete slabs. Concrete is pumped through a flexible pipeline system that is connected to the concrete pump at one end and pipes are assembled by suitable couplings. The hoses are generally manually attached and can also be joined to other extension hoses to reach the appropriate site where the concrete needs to be put. There are effective flap straight designs for concrete outlets and operator & maintenance-friendly design.

Truck mixer concrete pump

The mixer drums used in these concrete pump-mixers are of 7 to 9 cubic meters nominal capacity. It comes with a “Z” type folding system. Both Mobile and Static Pumps have a large hopper to receive concrete from a truck mixer. The latest models come with an upper-body equipped with almost a 28-meter / 4-arm boom with diameter installed together with a 9 cubic meter mixer. These pumps have become the basic tool for some concrete producers and the only tool to do the pumping work of supplying a few meters of concrete, as well as working as a typical concrete pump. Truck-mixer concrete pumps are ideal for supplying especially small construction sites with concrete in a simple and cost-efficient way. With the 1000 mm long-stroke pumping unit, these machines need fewer strokes with the result of reduced wear and lower fuel consumption. Also, these machines can easily reach delivery rates of more than 60 m³/h.

Specialized usage concrete pump

These types of concrete are created based on customization specifically for specialized job sites such as mines and tunnels. They are also skid mounted and rail mounted concrete pumps but are not commonly used due to their high costs and extra specialized mechanism.

Image Source: ajax-engg.com, schwingstetterindia.com, aquariusengineers.biz