Ceramic tiles come in a wide variety of colours and designs, with a style to fit any kind of decor. They are also incredibly durable and strong, and they are especially good floor tiles for high traffic areas. The main options include glazed, with an extra coating and several firings, more than the other option of unglazed, which usually only has one firing. Ceramic tiles usage depends on the situation and the environment they will be in. They come in a wide variety of different sizes and shapes, so it really depends on your personal liking and the kind of room you are tiling to determine the right kind to choose. Large tiles work great as flooring and smaller tiles make beautiful mosaic designs.

Ceramic tiles is a key building material used in the construction industry. They are stylish, durable, and versatile. They play an integral part in the décor of any space. Ceramic tiles are manufactured from various minerals and clays such as feldspar, zircon, bentonite, kaolin, and clay. Raw materials undergo various mechanical operations such as mixing, drying, and forming to yield the ceramic tile body.

Manufacturing of ceramic tiles

Ceramic tiles are manufactured from various minerals and clays such as feldspar, zircon, bentonite, kaolin, and clay. Raw materials undergo various mechanical operations such as mixing, drying, and forming to yield the ceramic tile body. The tile body is further heated at elevated temperatures in order to improve the tile porosity. Thus, resilient ceramic tiles are produced. Ceramic tiles are one of the key components used in the construction industry for building interior and exterior floors, footpaths, swimming pools, walls, partitions, and roofs. Ceramic tiles are highly durable. They offer protection from abrasion and stains and they require less maintenance. Additionally, these tiles are available in a wide range of sizes as well as colors. They are available at affordable prices. Ceramic tiles are extensively employed in various concrete structures ranging from residential houses such as flats, apartments, villas, and bungalows to commercial complexes such as hospitals, educational institutions, and airports. Furthermore, these tiles are used in the construction of industrial concrete structures such as food processing factories and warehouses.

Different types of ceramic tiles

Vitrified tile

Vitrified tile is a ceramic tile with very low porosity. It is an alternative to marble and granite flooring. Vitrified tiles are often used outdoors due to their water and frost resistance. There are four types of Vitrified tiles – Soluble salt, Double charge, Full Body, Glazed. Vitrified tile is made by hydraulic pressing a mixture of clay, quartz, feldspar and silica, which make vitreous surfaces. Thus creating a single mass making them hard with low porosity. Different clay bodies reach vitrification at different temperatures.

These tiles are minimized, scratch and corrosive safe and have better mechanical quality. They are basically replacing stone and marble as flooring because of their stone-like qualities, for example, consistent joint and uniform color and texture. They are more durable and scratch resistant.

Vitrified tiles are consistent in sizes, shades and thickness. They are easier to install and need practically no setting time or polishing after laying. Therefore they can be used within 48 hours after laying. Due to moisture resistant, vitrified tiles prevent bacteria and fungi from growing. The effect of sunlight neither alters the colour of the tiles nor causes them to fade.

Porcelain tile

Porcelain tiles are commonly used to cover floors and walls, with a water absorption rate of less than 0.5 percent. The clay used to build porcelain tiles is generally denser. They can either be glazed or unglazed. Porcelain tiles are one type of vitrified tiles, and are sometimes referred to as porcelain vitrified tiles. Historically, porcelain was not the usual material for tiles, which were much more often made of earthenware (terracotta) or stoneware. The first porcelain tiles were made in China, for example in the 15th-century Porcelain Tower of Nanjing (now largely destroyed). Here the tiles were used for walls, which long remained typical. In Europe, a few rooms were made in palaces of porcelain plaques, often with forms in high relief. Although porcelain has now been widely used for making tiles for many years, modern production methods and quantities have made porcelain tiles available for the average householder in recent years.

Porcelain is much harder than ordinary ceramic tiles and is usually selected, despite its higher price, for its hard wearing nature. Porcelain can be used in both wet and dry areas such as bathrooms, showers and kitchens. The dense, hard surface of porcelain has made polishing a viable alternative to a glazed surface. This means that a tile can be fired, then a polish cut into the surface, creating a shine without a glaze. These Versatile tiles accompany a plain, unpleasant, or cleaned complete and can be utilized as a part of insides and are a superb choice for open air conditions as they don’t wear easily under heavy traffic.

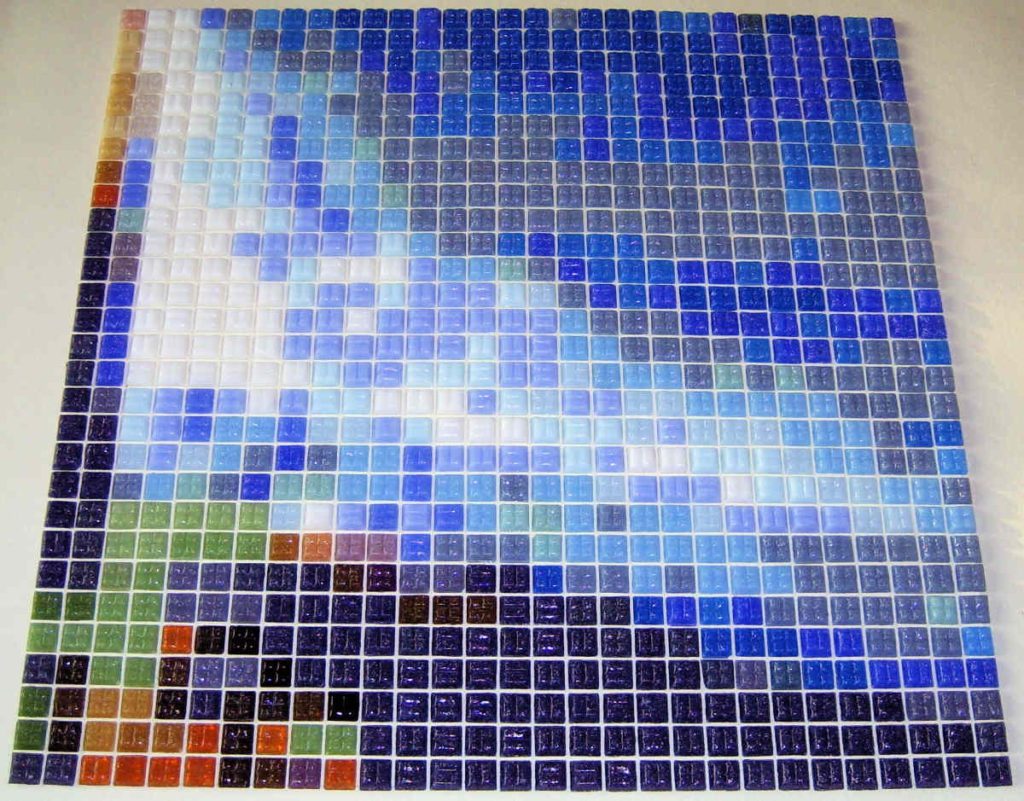

Mosaic tile

Mosaic tile is any combination of materials such as glass, ceramic, porcelain or stone, usually set in a small format and set on a mesh sheet for easy installation. Mosaics can be used several different ways to really bring that “wow” factor to your bathroom. A linear glass mosaic running vertically floor to ceiling can add a stunning waterfall effect. Conversely, a mosaic running horizontally in a shower, or in the back of a niche, could bring in that subtle pop of needed color. These are small tiles, around .75 inches to 1 inch in estimate mounted on paper sheets or latex work for simple establishment. These tiles can be ceramic, porcelain or glass and are most reasonable on walls, bended surfaces as paintings, in water pools, and low activity floors. They don’t chip effectively and because of various grout joints are slip safe as well.

Mosaic Tiles are one of the most popular and widely used tiles in the market. Their origin can be traced back to the Roman and Greek times. However, they have evolved with time and are now available in various different designs and patterns. These tiles are used to give a beautiful and original appearance to houses. Mosaic tiles are available in various different types such as ceramic mosaic, organic tiles, creative tiles, glass mosaics etc. which can be used for different purposes.

Mosaics are perfect to use as a backsplash in full, or as an accent with ceramic or stone subway style tile. Small or larger format mosaic tiles used as an entire backsplash are a great way to add dimension and character to a kitchen. It’s also a good way to ground all of the various colors and finishes in a kitchen and surrounding rooms. If the countertop wants to be the main focus of the space, you can either use a few inches of mosaic at the base of the backsplash and then transition into a stone or ceramic tile above, or you can simply break up a mosaic sheet and add one decorative strip as an elegant design element.

Glazed tile

The glazed ceramic tiles have a liquid glass coating on the surface. The liquid glass coating creates the texture, design, and color of a glazed tile and protects the body of the tile from staining. Due to this extra layer, custom tile designs can be added to them. This allows the floor tiles designs to be available in multiple colors. Due to their vibrant allure, there are mostly used as floor tiles for kitchen and bathroom walls.

These non permeable, smooth surface tiles are stain proof, most reasonable for low traffic areas, walls and countertops. The large configuration glazed tiles with satin complete are very mainstream nowadays. When it comes to the glaze itself, different options are available and will impact the degree of durability. Some varieties of glazed tile are fired at higher temperatures than others, and therefore are harder as well. This can often be determined by how light or dark the glaze is, with lighter glazes generally being harder than darker glazes.

Then there is the issue of gloss: matte and satin finishes are generally harder than shiny finishes. As always, it’s a good idea to try and strike a balance between practicality and decorative taste when choosing your glazed ceramic and porcelain tile.

Quarry tile

Quarry tile is a hard, impervious paving tile made from the ground minerals formed and fired in much the same way as is used to make brick. They are typically harder than ordinary clay bricks, due to the minerals used and the high firing temperatures. Unlike clay terracotta, quarry tiles are not porous and will resist water; and unlike ceramic tile and porcelain, quarry tile does not have a surface glaze layer.

Quarry tile is extensively used for floors where a very durable material is required. It can be used either indoors or outdoors, although freeze-resistant grades of tile should be used outdoors in climates where freeze-thaw action occurs. Quarry tile is used less often as a wall finish and is occasionally used for countertops, although the wide grout joints can make cleaning of countertops difficult. Most commercial kitchens require a quarry tile to be used because of its slip resistant and non-porous properties.

Quarry tile is a building construction material, usually 1⁄2 to 3⁄4 inch (13 to 19 mm) thick, made by either the extrusion process or more commonly by press forming and firing natural clay or shales. Quarry tile is manufactured from clay in a manner similar to bricks. It is shaped from clay, and fired at a high temperature, ~2,000 F°. For floors, quarry tile is usually set in a thick bed of cementitious mortar. For wall applications, it can be set in either a thick bed of cementitious mortar or a thin bed of mastic. For both floors and walls, the joints between tiles are usually grouted with cementitious grout. Grout joints are traditionally about 3⁄8 inch in width. Matching trim shapes such as coves, bases, shoes, and bullnoses are available to turn corners and terminate runs of the tile.

Terracotta tile

Terracotta translates from Italian as “baked earth,” and as a category of ceramic tile, it refers to tiles created from a particularly porous and easily shaped clay with a high iron content that gives the tiles their characteristic reddish/brown color. Terracotta is fired at a relatively low temperature (600 to 1,000 degrees Fahrenheit), and its surface remains quite porous unless it is glazed. Terracotta tile is readily available and less expensive than many other forms of ceramic. Its popularity stems largely from its attractive natural colors, which are the very epitome of earth-tones.

Terracotta tiles are sometimes categorized as high-density or low-density materials, though it is the “high density” label that is more often touted by manufacturers. High-density terracotta will be more resistant to cracking and is a better choice for heavy-use areas. Low-density terracotta is usually a bargain material that may not hold up well under heavy use. Low-density terracotta also is more porous, so it is not a good choice for wet areas or areas prone to stains, such as bathrooms and kitchen. These handmade assembled or machine made tiles are regularly used as rooftop tiles, they highlight a natural look and remain cool in summers and warm in winters however unglazed Terracotta tiles require a layer of sealer consistently.

Conclusion

Key factors driving the demand for ceramic tiles in the region include increases in consumer income, population growth, increased government initiatives for infrastructure development, and collaboration with foreign investors. The increasing number of new construction sites and increased renovation activities are the main drivers of the ceramic tile market in Asia Pacific. Resistant to stains, water and chemicals; Ceramic tiles are often used in the construction of residential and commercial buildings.

In terms of applications, the ceramic tile market has been segmented into a substitute for housing, commercial, new housing, and industry. The commercial segment (which includes office and sports complexes) is expected to grow significantly during the forecast period, due to future projects in the global building & construction industry.

Image Source: property24.com, mytyles.com, thespruce.com, kaamar.com, medium.com, designingbuildings.co.uk, doityourself.com